Emissions label mastery: The 3-step framework to understanding your emissions labels

A picture is worth a thousand words, sound familiar?

Article written by Tom Swaczyna. Tom is a mechanical engineer and writer who has a talent for breaking down complex topics into clear, engaging content. He brings fresh perspectives to tech and innovation, making it accessible and intriguing for industry experts.

Picture this: You are in the middle of selling your excavator, and just as you reach out to shake the customer’s hand to close the deal, he asks “What’s the emissions rating on this thing – is it EPA certified?” You pause, mentally sorting through a jumble of labels, stages, and regulations, the pressure is on. Do you stutter through a guess, or confidently explain it like a pro? Every second counts.

Now imagine a different story: This time, when the question comes, you light up. You easily decode the alien language on the emissions label, leaving the customer impressed and ready to buy. That’s the power of emissions label mastery.

With this 3-step emissions label mastery framework, you’ll go from label confusion to clarity faster than you can bust out your phone and google it. Ready to turn a headscratcher into your secret weapon?

“What’s the emissions rating on this thing – is it EPA certified used equipment?

Let’s get started!

With this 3-step framework, you will:

- Understand the basics of emissions tiers and stages.

- Decode the key information on an emissions label.

- Confidently apply this knowledge in real-world scenarios.

Step 1: Understand the basics of emissions stages and tiers

Emissions standards are designed to reduce harmful pollutants like nitrogen oxides (NOx) and particulate matter (PM) from diesel engines. Depending on the region and regulatory body, these standards are broken down into different stages or tiers.

- Europe: Uses “Stages” (Stage I to Stage V).

- United States: Uses “Tiers” (Tier 1 to Tier 4).

The stages and tiers represent varying levels of strictness in emissions control. As the numbers increase, the regulations become more stringent. For example, a Stage IV engine in Europe or a Tier 4 Final engine in the United States is designed to emit considerably less than a Stage II or Tier 2 engine.

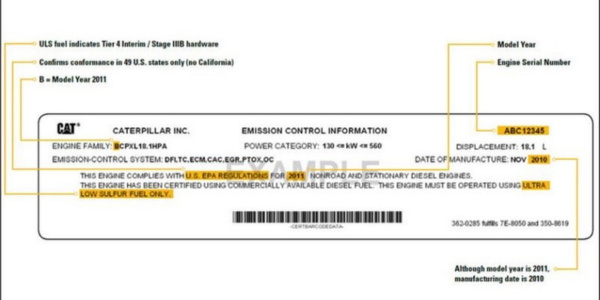

Step 2: Decode the emissions label

Now that you know the basics of tiers and stages, let’s break down what’s on an emissions label. Here’s what you’ll typically find:

- Manufacturer information: Tells you who made the engine or machine.

- Emissions stage/tier: Usually listed as “Stage IV” or “Tier 4 Final.” This is your quick reference to how the machine meets emissions standards.

- Engine family: A code identifying a group of engines with similar emissions characteristics.

- Displacement and power: Engine size and power output, are often related to emissions levels.

- Emissions control technologies: Labels often specify if technologies like SCR (Selective Catalytic Reduction) or DPF (Diesel Particulate Filter) are used. Click here for a list and description of the technology acronyms

Example: Let’s say you’re looking at the emissions label on a Caterpillar C7.1 engine. It reads “Tier 4 Final, 7.1L displacement, 200 kW power, equipped with DOC and SCR.”

This tells you the engine meets strict Tier 4 Final emissions standards, which means it produces very low pollution. The engine uses DOC (Diesel Oxidation Catalyst) and SCR (Selective Catalytic Reduction) to reduce harmful emissions like nitrogen oxides (NOx) and particulate matter (PM), making it a cleaner, more efficient option for heavy machinery.

Step 3: Apply your knowledge in real-world scenarios

Grasping the concept is one aspect, but the real magic lies in applying that knowledge.

Whether on a sales call, in the field, or while managing a fleet, understanding the effects of emissions standards on machinery performance can be transformative.

For sales professionals: Turn emissions compliance into a selling point. A Tier 4 Final or Stage V machine may have a higher upfront cost. But it will often have better fuel efficiency and may meet the latest regulations, saving the customer money in the long run. Plus, it future-proofs their investment.

For operators and fleet managers: Knowing your emissions labels can help you manage your machines’ operational costs and efficiency. Lower-tier machines might cost less, but they can incur fines or be restricted in certain regions with stricter emissions laws. Conversely, machines with higher emissions standards often run more efficiently, lowering fuel costs over time.

Example scenario: Imagine you’re managing a construction fleet in a region with strict emissions laws. The city mandates that only Tier 4 Final machines can be used on-site. By knowing which of your machines meet those standards, you can avoid fines, reduce downtime, and ensure compliance with the law.

Emissions labels may seem complex at first glance. But by breaking them down and using this framework, it can become a powerful tool in your arsenal.

Understanding and explaining emissions labels can give you the upper hand in any situation.

Also read, Prepare your construction equipment for winter: Essential maintenance tips for antifreeze, batteries, and more

One last thing

Please support Fused Equipment, by leaving a comment.

Follow Fused Equipment on LinkedIn and Facebook to stay updated on the latest happenings.

Have a question about this content or want to get in contact with a rep to discuss your emissions label? Contact us. Fused Equipment www.FusedEquipment.com